Recomissioning an original WattsOn meter (prior Fat Spaniel / Power One / ABB installation)

WattsOn-1100/-1200 meters originally deployed by Fat Spaniel (FST, later Power One, later ABB) are often no longer supported by the original supplier/monitoring company. These meter may be recommissioned into a new system, but they must be reconfigured. Additionally, it is recommended that the new datalogger/monitoring system be reprogrammed to make use of the floating point registers.

Original WattsOn manual:

http://elkor.net/pdfs/WattsOn_Manual.pdf

- FST installations had some configuration quirks: Namely, FST used the integer Modbus registers to read the data. The meter features two identical register banks: integer and floating point. The integer registers are NOT scaled by the CT and PT ratios, thus change these value will not affect the readings from the integer registers. Additional information on data scaling and interpretation is on page 15 of the manual.

The integer registers were intended to be scaled by the end user/datalogger by the corresponding CT ratio. This is one possible option for a new system, if the datalogger can facilitate this. Please review the knowledge base article regarding CT ratios:

http://support.elkor.net/knowledgebase.php?article=6

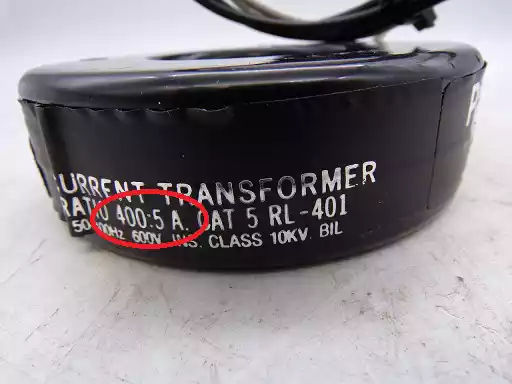

Otherwise, it is best to reconfigure the datalogger to read the floating point registers, which will be scaled by the CT/PT ratio settings. These registers are described on page 14 of the manual. - In the case of a 5A CT meter (marked on the front, and in the part number), the CT ratio will be xxx:5. The CT Ratio should be marked on the CTs (see photo below). Elkor did not supply FST with the 5A CTs, so there is no way for us to reference sales history for this information. If the CT is not clearly marked, the ratio can usually be determined from searching up the part number.

- The CT and PT ratio settings are accessible via Modbus (page 17). If the new datalogger/RTU can read/write Modbus registers, then it can possibly be used to change these settings.

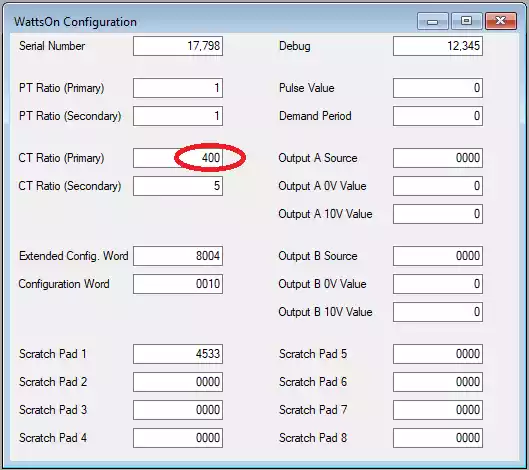

Although FST did not use the CT/PT registers for scaling, they did use the PT register as a placeholder for their own configuration data. Typically, the PT (primary) register was set to “3”. If the new system reads the floating point registers, this setting will have the effect of multiplying the voltages (and currents, energy) by a factor of “3”. - To configure the meter, the settings should be:

PT Ratio (primary): 1

PT Ratio (secondary): 1

CT Ratio (primary): xxxxx (Review the CT Ratios article: http://support.elkor.net/knowledgebase.php?article=6)

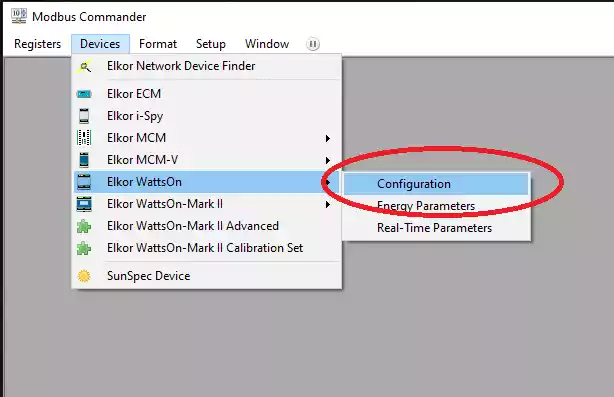

CT Ratio (secondary): 5 - The PT/CT Ratios are configured via Modbus, however our free software, Modbus Commander (http://elkor.net/product/WattsOn-Mark_II#Software) may be used, as it provides a simpler, graphical interface. This software requires an RS-485 connection to the meter (Modbus/TCP may also be used in case the new datalogger supports Modbus/TCP to Modbus/RTU conversion).

After establishing a connection with the meter, navigate to “Devices > Elkor WattsOn > Configuration” (see screenshot). Assuming that the communication settings are working, the fields should populate with the current settings, which can then be changed as required. - Elkor's newer WattsOn-Mark II may be considered as an upgrade path from an existing WattsOn meter.

http://elkor.net/product/WattsOn-Mark_II

The WattsOn-Mark II has several advantages including higher accuracy and additional options such as on-board display, datalogging, and ethernet/wifi, which includes access to our free Cloud service, which could possibly replace the need for a separate datalogger:

http://elkor.net/product/Cloud

Considering the age of these meters and systems, Elkor's support services are limited outside the scope of this knowledgebase. The meters are very reliable and users should have no issues in deploying them in new systems. Additional deployment and configuration assistance is available as a paid service from Elkor Technologies Inc.